Metal conveyor belts are an essential component of many industrial processes. They play a critical role in transporting heavy loads of raw materials, finished products, and other items in factories, mines, and other facilities. However, like any other equipment, metal conveyor belts are subject to wear and tear, which can affect their performance, reliability, and lifespan. Therefore, it is essential to maintain and repair metal conveyor belts regularly to ensure their longevity, efficiency, and safety. In this article, we will discuss some practical tips on how to maintain and repair metal conveyor belts for longevity.

Introduction

Metal conveyor belts are commonly used in industries such as food processing, automotive manufacturing, mining, and pharmaceuticals. They are durable, flexible, and able to withstand high temperatures, heavy loads, and harsh environments. However, metal conveyor belts are also susceptible to wear and tear, which can lead to reduced performance, safety hazards, and increased downtime. Therefore, it is crucial to maintain and repair metal conveyor belts regularly to ensure they function optimally and last longer.

Understanding Metal Conveyor Belts

Metal conveyor belts consist of a series of interlocking metal plates or links that form a continuous belt. They are commonly made of stainless steel, carbon steel, or other alloys, depending on the specific application. Metal conveyor belts are available in various configurations, including flat wire, round wire, chain-driven, and balanced weave. They can transport a wide range of materials, including raw materials, finished products, and waste.

Causes of Metal Conveyor Belt Wear and Tear

Several factors can cause wear and tear on metal conveyor belts, including:

- Abrasion: caused by the friction between the belt and the transported material or equipment

- Corrosion: caused by exposure to moisture, chemicals, or other environmental factors

- Fatigue: caused by repeated loading and unloading, which can weaken the belt’s structure over time

- Misalignment: caused by improper tensioning, tracking, or installation, which can cause the belt to rub against other components

- Overloading: caused by exceeding the belt’s weight capacity, which can lead to excessive stress and deformation

Common Types of Metal Conveyor Belt Damage

Common types of metal conveyor belt damage include:

- Cracks and tears: caused by overloading, impacts, or sharp edges

- Deformation: caused by improper tensioning, tracking, or bending

- Wear and abrasion: caused by friction and exposure to abrasive materials

- Corrosion and rust: caused by exposure to moisture, chemicals, or high temperatures

Importance of Regular Maintenance and Inspection

Regular maintenance and inspection are essential for ensuring the longevity and safety of metal conveyor belts. Maintenance involves cleaning, lubrication, tensioning, tracking, and repair of damaged parts, while inspection involves identifying potential problems, monitoring performance, and taking corrective actions. By performing regular maintenance and inspection, operators can:

- Prevent costly downtime and repairs

- Improve efficiency and productivity

- Extend the lifespan of the conveyor belt

- Ensure safety and compliance with regulations

- Reduce environmental impact

Tips for Maintaining and Repairing Metal Conveyor Belts

Proper maintenance of metal conveyor belts can help prevent potential problems and increase their lifespan. Here are some tips to keep in mind:

Proper Cleaning

Regular cleaning is essential to keep metal conveyor belts in good condition. Dirt and debris can accumulate on the belt, causing it to wear out quickly or even break. Use a soft brush or a damp cloth to remove any loose particles or dirt. Avoid using harsh chemicals or abrasive materials that can damage the belt’s surface.

Regular Inspection

Conducting regular inspections can help identify potential problems before they become more significant. Inspect the belt for any signs of wear and tear, damage, or misalignment. Check the belt’s tension and make adjustments if necessary. Look for loose parts, such as screws or bolts, and tighten them if needed.

Tightening Loose Parts

Loose parts on a conveyor belt can cause the belt to malfunction or even break. Check for any loose screws, nuts, bolts, or other fasteners, and tighten them if needed. Make sure to use the appropriate tools and equipment to avoid damaging the belt or the fasteners.

Lubrication

Lubricating the metal conveyor belt can help reduce friction and prevent wear and tear. Use a suitable lubricant, such as silicone or graphite, and apply it evenly to the belt’s surface. Avoid using too much lubricant as it can attract dirt and debris, causing more harm than good.

Tips for Repairing Metal Conveyor Belts

Even with proper maintenance, metal conveyor belts may require repairs from time to time. Here are some tips on how to repair them:

Identifying the Problem

The first step in repairing a metal conveyor belt is identifying the problem. Conduct a thorough inspection to determine the issue’s cause and the extent of the damage. This will help you determine the appropriate repair method.

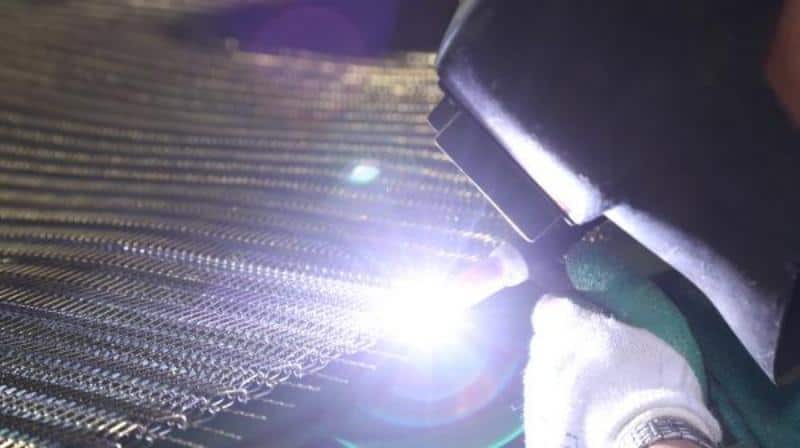

Repairing Cracks and Tears

Small cracks and tears can be repaired by applying a patch or using a metal adhesive.